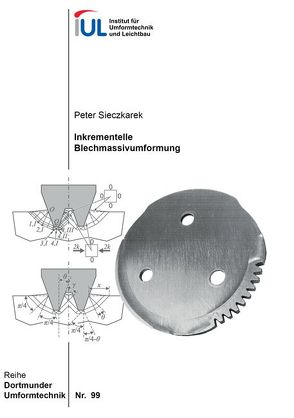

Inkrementelle Blechmassivumformung

Peter Sieczkarek

A new forming class called incremental sheet-bulk metal forming (iSBMF) has been established in order to fulfill future economical and ecological requirements, particularly in the automotive sector. Typical applications are weight- and load-optimized functional components, e.g. for starter gears, synchronizer rings or seat adjusters. Within the trend of individualization, a flexibility of manufacturing processes is necessary for a high variety of products. Incremental forming processes can provide the required flexibility because the workpiece geometry is defined by kinematic strategies of simple forming tools.

The iSBMF is defined as the incremental forming of sheets with a controlled threedimensional material flow by applying localized bulk forming operations to sheet metals with initial thicknesses of 2 – 3 mm. A characteristic feature is the small forming zone in comparison to the workpiece volume, and thus, lower forming forces occur. The key innovation is the defined control of the 3D material flow in a sequence of forming operations. A special forming press with five axes of motion was realized for this purpose and allows for a variety of different forming operations.

The local setting of the workpiece contour, the sheet thickness and the hardening based on individual requirements are the most important advantages provided by this incremental approach. For the fundamental process understanding of the iSBMF processes, analytical frameworks were developed to offer a physical insight into the deformation mechanics and to estimate the influence of the main process parameters on the force requirements. For the forming of defined functional elements, such as gears or carriers, a constructive restriction of the material flow is necessary and was realized by an appropriate workpiece chambering. Challenges during the incremental gear forming regarding a high tool wear and an insufficient formfilling of the gear elements formed were faced and solved within this work.